Zirconia Toughened Alumina | Al2O3/ZrO2

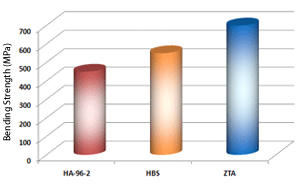

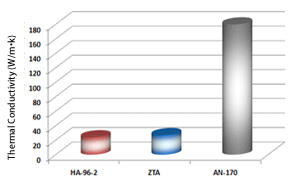

Zirconia Toughened Alumina has improved bending strength and higher reflectivity than alumina and AlN. These qualities combined with good heat dissipation means that they are ideal for LED package and power module for automotive and sustainable energy technologies.

Material Characteristics for Alumina Substrates (Al2O3), Zirconia Toughened Alumina Substrates ( Al2O3/ZrO2), Aluminium Nitride Substrates (AlN), and Silicon Nitride (Si3N4)

| Condition | Unit | Al2O3 | Al2O3/ZrO2 | AlN | Si3N4 | |||||||

| AS970 | HA-96-2 | HBS | HRA | HA-996 | ZTA | HRZ | AN-170 | SN-90 | ||||

| Material | - | - | 96.5% | 96% | 96.5% | 96% | 99.6% | Al2O3/ZrO2 | Al2O3/ZrO2 | AlN | Si3N4 | |

| Color | - | - | White | White | White | White | White | White | White | Gray | Gray | |

| Bulk density | - | g/㎤ | 3.74 | 3.75 | 3.75 | 3.60 | 3.90 | 4.00 | 3.85 | 3.30 | 3.22 | |

| Surface roughness Ra | - | µm | 0.4 | 0.4 | 0.3 | 0.3 | 0.1 | 0.2 | 0.2 | 0.2 | 0.4 | |

| Reflectivity | 0.3-0.4mmt | % | 70 | 70 | 70 | 85 | 75 | 80 | 87 | 35 | - | |

| 0.8-1.0mmt | 80 | 80 | 80 | 95 | 85 | 90 | 97 | 25 | - | |||

| Mechanical | Bending strength | 3-point method | MPa | 450 | 400 | 500 | 370 | 470 | 700 | 550 | 450 | 800 |

| Modulus of elasticity | - | GPa | 330 | 330 | 330 | - | 330 | 310 | - | 320 | 310 | |

| Vickers hardness | - | GPa | 14 | 14 | 14 | - | 16 | 15 | 14 | 11 | 15 | |

| Fracture toughness | IF method | MPa・m1/2 | 3.0 | 3.0 | - | - | - | 3.5 | - | 3.0 | 6.5 | |

| Thermal | Coefficient of thermal expansion | 40-400°C | 10-6/K | 6.7 | 6.7 | 6.7 | 6.7 | 6.8 | 7.1 | 7.1 | 4.6 | 2.6 |

| 40-800°C | 7.8 | 7.8 | 7.8 | 7.8 | 7.9 | 8.0 | 8.0 | 5.2 | 3.1 | |||

| Thermal conductivity | 25°C | W/(m・K) | 24 | 24 | 24 | 20 | 29 | 27 | 23 | 180 | 85 | |

| 300°C | 12 | 12 | 12 | - | 13 | 16 | - | 120 | - | |||

| Specific heat | 25°C | J/(㎏・K) | 750 | 750 | 750 | 750 | 780 | 720 | 720 | 720 | 680 | |

| Electrical | Dielectric constant | 1MHz | - | 9.8 | 9.8 | 9.8 | - | 9.9 | 10.2 | - | 8.5 | 7.8 |

| Dielectric loss factor | 1MHz | 10-3 | 0.2 | 0.2 | 0.2 | - | 0.2 | 0.2 | - | 0.3 | 0.4 | |

| Volume resistivity | 25°C | Ω・㎝ | >1014 | >1014 | >1014 | >1014 | >1014 | >1014 | >1014 | >1014 | >1014 | |

| Breakdown strength | DC | ㎸/㎜ | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 | >15 | |

Characteristic Values

List of Products

Heat dissipation substrate for automotive, sustainable energy and LED package application