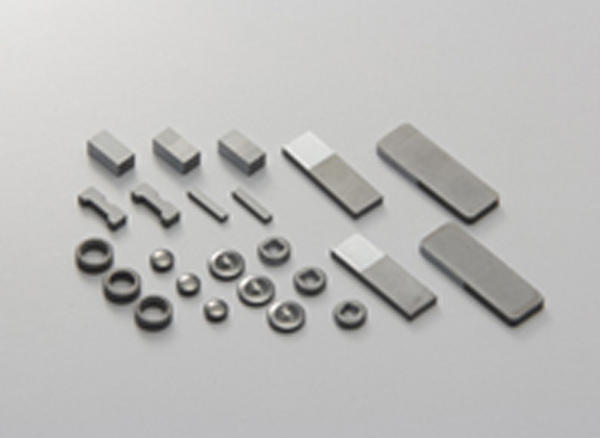

Ferrite Magnets

Features

Applications

Communication equipment, Motor, Adsorption, Relay, Medical, Sensor, etc.

Standard Material Characteristics

| Material | Classification | Residual Flux Density <Br> | Coercive Force <BHc> | Maximum Energy Product <(BH)max> | Density(g/㎤) | Curie Temp. (°C) | Thermal Expansion Coefficient (10-5/°C) | |

| Q2 | Isotropic | (Ba Type) | T 0.20~0.24 | kA/m 127~160 | kl/㎥ 7.1~10.4 | 4.9~5.0 | 460 | 0.9~1.5 |

| G 2,000~2,400 | Oe 1,600~2,000 | MGOe 0.9~1.3 | ||||||

| Q6 | Wet Anisotropic | (Ba Type) | T 0.40~0.43 | kA/m 143.3~175 | kl/㎥ 28.8~32.0 | 5.0~5.2 | 450 | 0.9~1.5 |

| G 4,000~4,300 | Oe 1,800~2,200 | MGOe 3.6~4.0 | ||||||

| SR-2H | Wet Anisotropic | (Sr Type) | T 0.38~0.41 | kA/m 262~287 | kl/㎥ 27.0~32.0 | 4.75~4.95 | 460 | 0.9~1.5 |

| G 3,800~4,100 | Oe 3,300~3,600 | MGOe 3.4~4.0 | ||||||

| SR-3 | Wet Anisotropic | (Sr Type) | T 0.41~0.43 | kA/m 215~247 | kl/㎥ 32.0~35.2 | 4.8~5.0 | 460 | 0.9~1.5 |

| G 4,100~4,300 | Oe 2,700~3,100 | MGOe 4.0~4.4 | ||||||

| SR-30 | Dry Anisotropic | (Sr Type) | T 0.34~0.38 | kA/m 222~255 | kl/㎥ 20.6~24.5 | 4.8~5.0 | 460 | 0.9~1.5 |

| G 3,400~3,800 | Oe 2,800~3,200 | MGOe 2.6~3.2 | ||||||

| SR-40 | Dry Anisotropic | (Sr Type) | T 0.36~0.39 | kA/m 218~251 | kl/㎥ 23.0~27.9 | 4.9~5.1 | 460 | 0.9~1.5 |

| G 3,600~3,900 | Oe 2,750~3,150 | MGOe 2.9~3.5 | ||||||

| SR-40S | Dry Anisotropic | (Sr Type) | T 0.38~0.41 | kA/m 214~247 | kl/㎥ 27.0~31.9 | 4.9~5.1 | 460 | 0.9~1.5 |

| G 3,800~4,100 | Oe 2,700~3,100 | MGOe 3.4~4.0 | ||||||

Substance Characteristics

| Item | Unit | Range | |

| Transverse Strength | Kgf/㎟ | 5~9 | |

| Tensile Strength | Kgf/㎟ | 2~5 | |

| Vickers Hardness | 400~700 | ||

| Thermal Expansion Confficient | Anistropic Direction | ×10-6/K | 14~15 |

| Anistropic Square Direction | ×10-6/K | 9~10 | |

| Thermal Conductivity | W/m・K | ~5.8 | |

| Specific Heat | J/kg・K | 630~840 | |

| Temprature Coefficient | ⊿Br/Br/°C | -0.18~0.20 | |

| ⊿Hc/Hc/°C | +0.20~+0.50 | ||

| Electrical Resistance | Ω・㎝ | >104 | |

| Recoil Permeability | µrec | 1.05~1.20 | |

| Magnetizing Power Required for Magnetization | kOe | 10 | |

| kA/m | 796 | ||