Ceramic Substrates

Metallized / Multilayer Ceramic Substrates

Ultra High Purity SiC Components

Pressed Ceramic Products

AlN

MARUWA Aluminum Nitride (AlN) Products

Aluminum nitride (AlN) properties include excellent thermal conductivity, high electrical insulation, and silicon-like thermal expansion. It is used for power transistor module substrates, laser diode mounting substrates, and in IC packages as a high thermal conductivity substrate material.

It is also used for semiconductor manufacturing equipment because of its excellent corrosion resistance to halogen gas.

MARUWA has an integrated production system encompassing material development, sheet molding, and firing. By combining elemental technologies such as lamination, thin filming, metallization, co-firing, and circuit design, we are able to produce customized products that suit our customers' needs.

Our expertise isn't only in ceramic materials but also high-frequency circuits. MARUWA has a solution for your needs.

Product Lineup

MARUWA's Proprietary Technology of Aluminum Nitride (AlN) Product Lineup

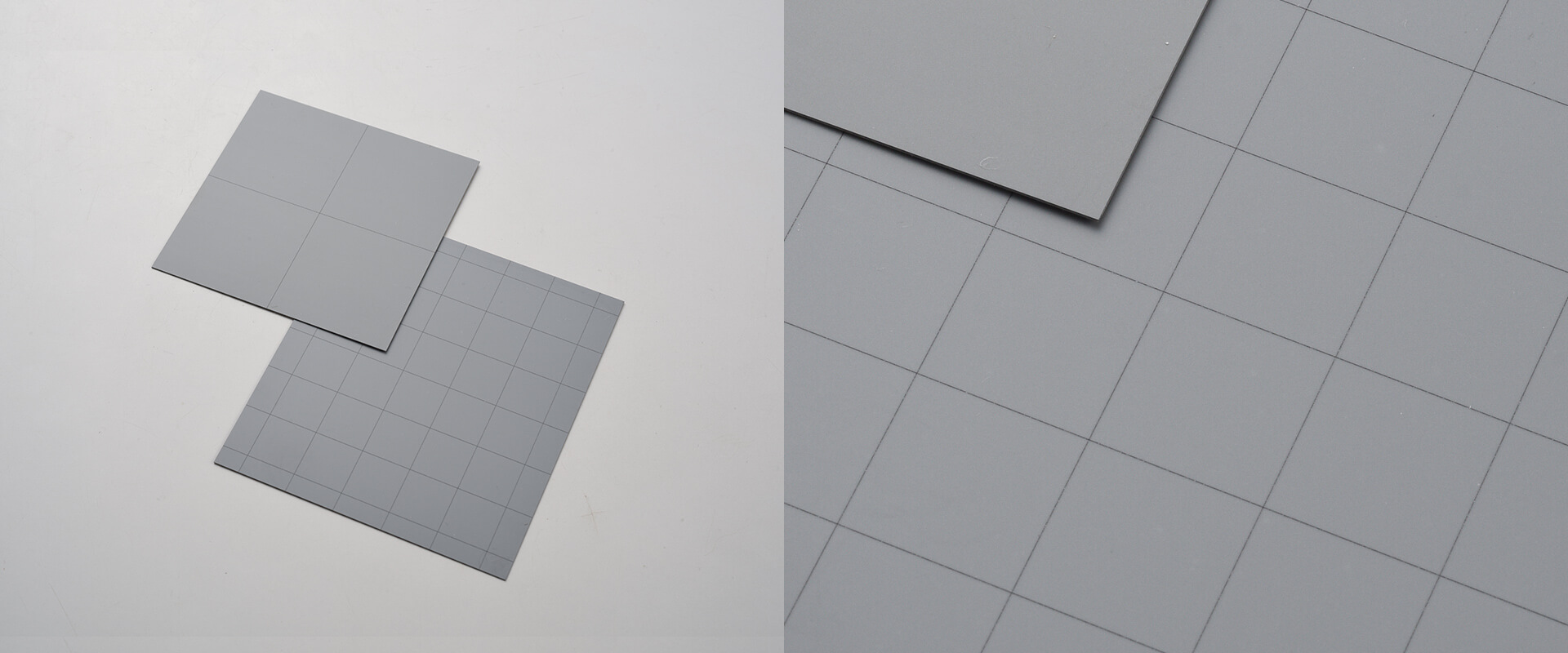

Aluminum Nitride (AlN) Substrates

We have established a stable mass production system for aluminum nitride (AlN) based on material technologies, sheet molding, and firing skills, which are cultivated by manufacturing alumina substrates.

We meet our customer's needs by providing different types of thermal conductivity, strength, and thickness.

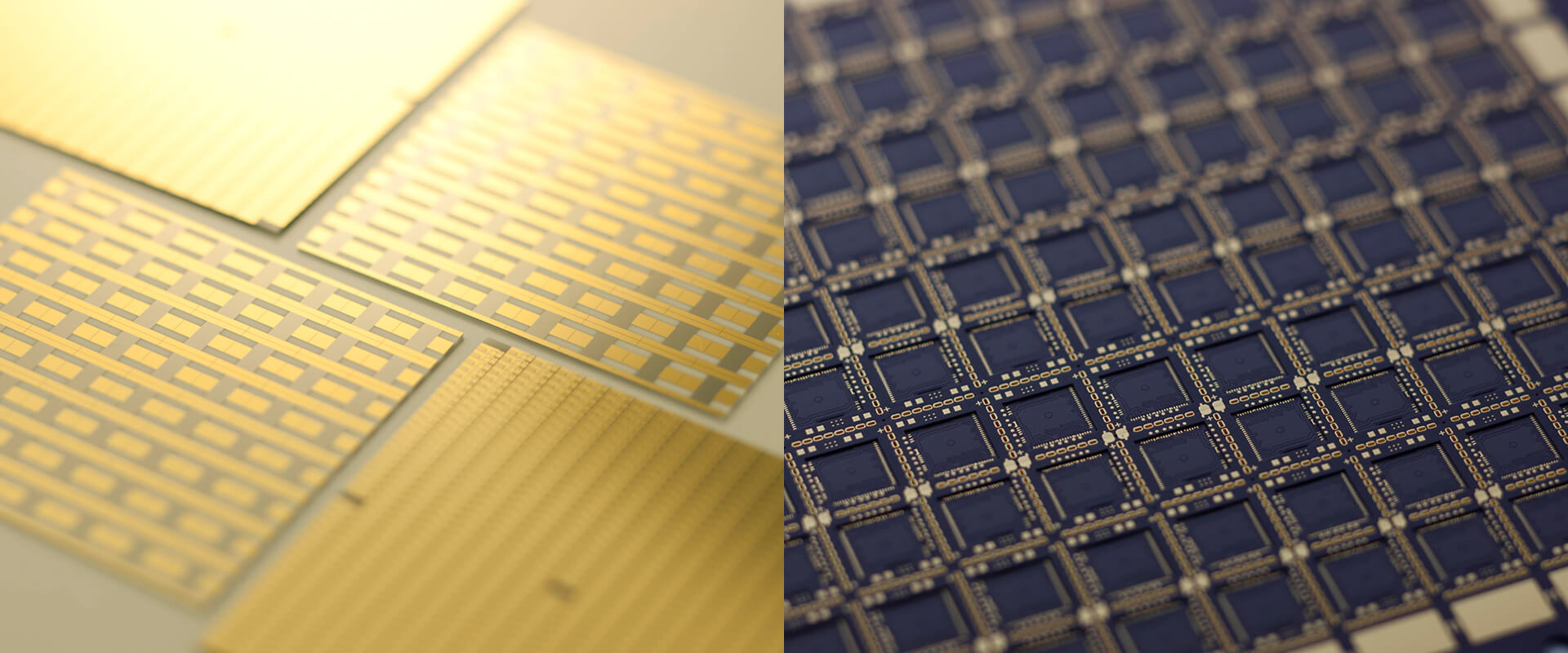

Customized Processed Products of Aluminum Nitride (AlN)

We provide customized products that meet our customer's needs by combining thin film sputtering, thick film printing, plating metallization, and multilayer/laminating technology with aluminum nitride (AlN) substrates.

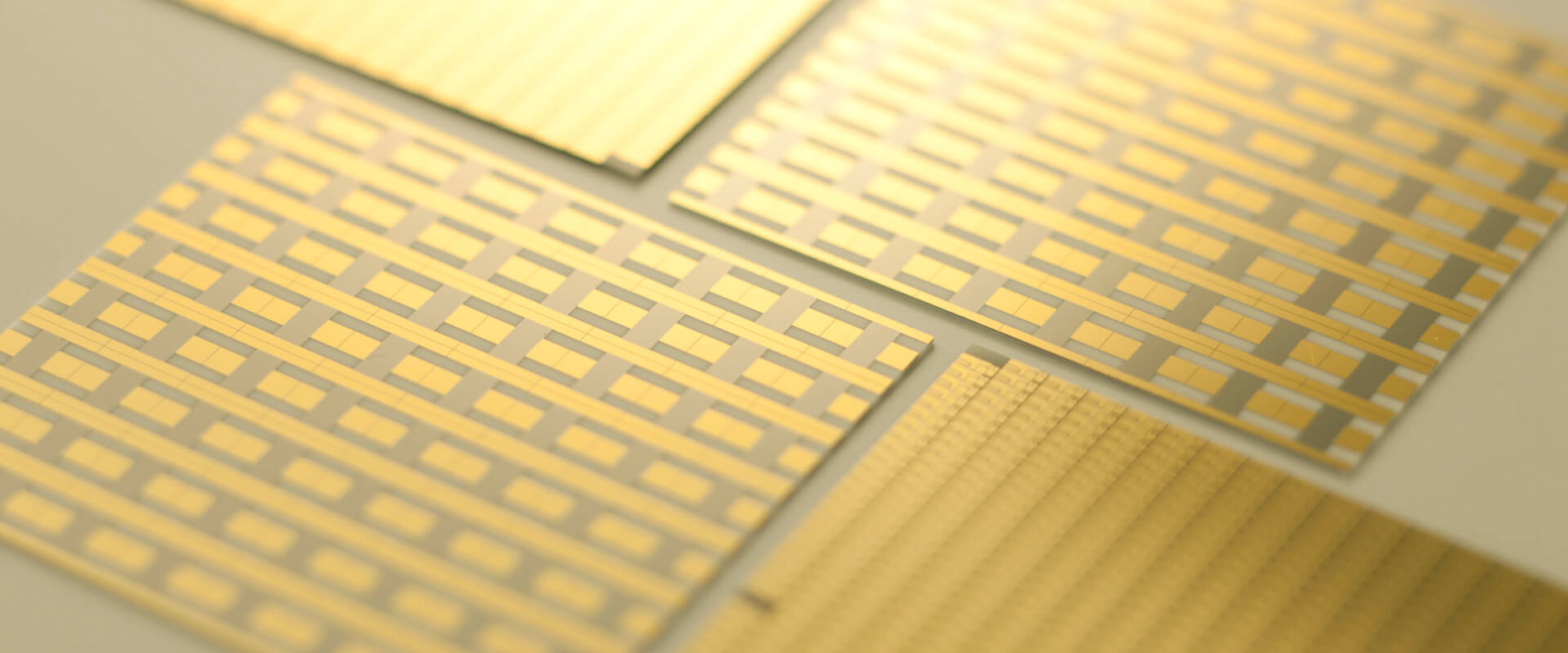

Thin Film Sputtering

MARUWA has in-house integrated production using substrate moldings and sputtering processing. Our consolidated quality management system makes high-quality metallization processing possible.

Thick Film Circuit Pattern Printing

Thick film printing · Via filling can be applied even on aluminum nitride (AlN) substrates. Although it is a general processing skill for alumina substrates, MARUWA's sheet forming and metallization technologies make it possible.

Plating Electrode Technology

Combined with thin and thick film technology, we form an electrode through plating. Since MARUWA does thin and thick film processing, we realize high-quality plated electrodes through integrated in-house production.

Co-fired Laminating Technology

Co-fired laminating technology metalizes, drills and forms circuits on raw sheets, then laminates and co-fires them. This is one of MARUWA's unique technologies developed through our AlN expertise.

Aluminum Nitride (AlN) Filler

Thermally conductive filler produced by MARUWA, a ceramic material technology professional, realized high thermal conductivity, high purity, high packing properties, and shape variations by making the most of original material properties of aluminum nitride (AlN).

We provide aluminum nitride (AlN) filler according to our customer's use and purposes.

Aluminum Nitride (AlN) Parts for Semiconductor Manufacturing

Utilizing the high thermal conductivity and high corrosion resistance of aluminum nitride (AlN), they are used for semiconductor manufacturing equipment. MARUWA provides parts for semiconductor manufacturing and medical equipment by using our original sintering process suitable for production, shaping, and various machining processes based on our material technology created over the years.

Information Request and Inquiries

Feel free to contact us about estimates, product specifications, and customization.