Thick Film Substrates & Packages (Plating)

Features

Applications

Submount substrate for industrial equipment and medical equipment

Standard specification for Thick Film Metallization (Plating)

| Item | Standard Specification | ||

| Substrate Material | Material | Aluminum Nitride (AlN) | Themal conductivity 170W,200W,230W |

| Thickness | 0.25~1.00mmt | - | |

| Work Size | 50.8□(2inch□),2inch×4inch□ | ||

| Film Specification | Film Composition | electrolytic plating NiAu specification:Cu / Ni / Au=20~80μm / >1μm / >0.5μm(MW recommendation) | |

| Film Thickness | Cu thickness:30~80±15μm(standard),±10μm(special) | ||

| Solder | AuSn composition:(eg)Au / Sn=75 / 25±5wt%(ratio is flexible) | ||

| AuSn thickness: 1.5μm~7μm±20% | |||

| Pattern | Accuracy L / S=100μm / 150μm(Cu thickness over 50μm),50μm / 80μm(Cu thickness 30μm target) | ||

| others | Cutting process | ±50μm( speical ±20μm) | |

-

electrolytic plating NiAu specification (MW recommendation)

In the case of electrolytic specification, an electrode wire is required for each land Thickened Au is possible. (Standard thickness about 1.5 μm

| Item | Inspection Item | Measurement Inspection Machines |

|---|---|---|

| Quality Assurance | Size | Measuring Microscope |

| Film Thickness | X-ray Fluorscence, Surface Rough Meter | |

| Resistance | Digital Multi Meter | |

| Externals | Microscope | |

| Wire Strength | Pltester |

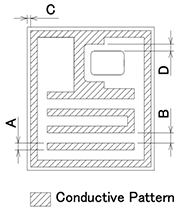

Pattern accuracy

| Dimension position | Minimum Size |

|---|---|

| A Conducter Size | 0.100mm |

| B Pattern Interval | 0.150mm |

| C Substance Thickness - Pattern Interval | 0.050mm |

| D Pattern - Hole Interval | 0.100mm |