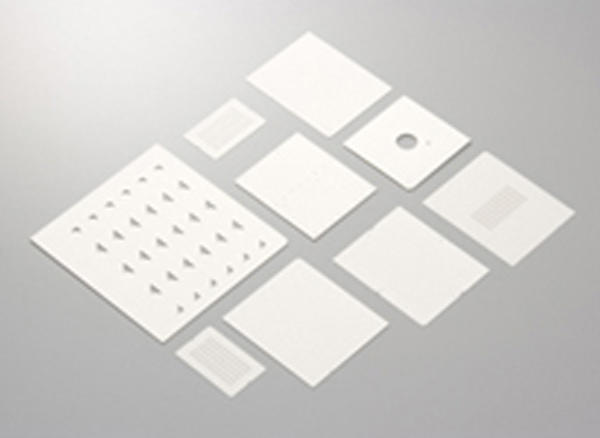

Alumina Substrates

Features

MARUWA has produced alumina (Al2O3) substrates for over 40 years under severe quality control with carefully selected high purity ceramic materials that ensures stable quality and excellent properties.

Our alumina substrate has well-balanced properties of insulation, thermal conductivity and breaking strength. Moreover, one of the unique properties is its surface roughness. We can provide the ceramic substrate which is excellent in adhesion with a thin film and thick film metalization due to fine particles.

-

Good smoothness / flatness with less porosity. Excellent in adhesion with thin film and thick film materials.

-

Less variance in outline, plate thickness, etc.

-

Minimal warpage, bending, and undulation.

-

Physical and chemical properties are stable even under a hot environment. Excellent in thermal shock resistance. High thermal conductivity and coefficient of thermal expansion similar to that of silicon.

-

Superior mechanical strength. Products with higher mechanical strength are also in our lineup.

-

Excellent resistance against oil and chemical.

-

Excellent in insulation properties, high dielectric breakdown voltage, high surface resistivity / volume resistivity, and small dielectric constant.

-

The high reflective substrate, especially suitable for optical applications such as LED, is also available.

Applications

LED packages, Power modules, FAX substrates for thermal printer head

*Various processing is available (thin film metalization, thick film metalization, glaze, etc.)

Characteristic Values

| Condition | Item | Al203 | ||||||

| AS970 | HA-96-2 | HBS | HRA | HA-996 | ||||

| Material | - | - | 96.5% | 96% | 96.5% | 96% | 99.6% | |

| Color | - | - | White | White | White | White | White | |

| Bulk density | - | g/㎤ | 3.74 | 3.75 | 3.75 | 3.60 | 3.90 | |

| Surface roughness Ra | - | µm | 0.4 | 0.4 | 0.3 | 0.3 | 0.1 | |

| Reflectivity | 0.3-0.4mmt | % | 70 | 70 | 70 | 85 | 75 | |

| 0.8-1.0mmt | 80 | 80 | 80 | 95 | 85 | |||

| Mechanical | Bending strength | 3-point method | MPa | 450 | 400 | 500 | 370 | 470 |

| Modulus of elasticity | - | GPa | 330 | 330 | 330 | - | 330 | |

| Vickers hardness | - | GPa | 14 | 14 | 14 | - | 16 | |

| Fracture toughness | IF method | MPa・m1/2 | 3.0 | 3.0 | - | - | - | |

| Thermal | Coefficient of thermal expansion | 40-400°C | 10-6/K | 6.7 | 6.7 | 6.7 | 6.7 | 6.8 |

| 40-800°C | 7.8 | 7.8 | 7.8 | 7.8 | 7.9 | |||

| Thermal conductivity | 25°C | W/(m・K) | 24 | 24 | 24 | 20 | 29 | |

| 300°C | 12 | 12 | 12 | - | 13 | |||

| Specific heat | 25°C | J/(㎏・K) | 750 | 750 | 750 | 750 | 780 | |

| Electrical | Dielectric constant | 1MHz | - | 9.8 | 9.8 | 9.8 | - | 9.9 |

| Dielectric loss factor | 1MHz | 10-3 | 0.2 | 0.2 | 0.2 | - | 0.2 | |

| Volume resistivity | 25°C | Ω・㎝ | >1014 | >1014 | >1014 | >1014 | >1014 | |

| Breakdown strength | DC | ㎸/㎜ | >15 | >15 | >15 | >15 | >15 | |

General Dimensional Tolerances

| Item | Unit | Al203 | ||||

| AS970 | HA-96-2 | HBS | HRA | HA-996 | ||

| Dimension | inch(max) | 4"×4" | 4"×16" | 5.5"×7.5" | 5.5"×7.5" | 4.5"×4.5" |

| Tolerance | ±0.6% | ±1.0% | ±1.0% | ±1.5% | ±1.0% | |

| Thickness | ㎜ | 0.10~0.50 | 0.25~1.20 | 0.25~1.0 | 0.25~1.0 | 0.25~1.0 |

| Tolerance | ±10% | ±10% | ±10% | ±10% | ±10% | |

| Through hole | ㎜ | Φ0.14~0.80 | Φ0.2~ | Φ0.2~ | Φ0.2~ | Φ0.2~ |

| Tolerance | ±0.6% | ±0.6% | ±0.6% | ±0.6% | ±0.6% | |

| Warpage | ㎜ | 0.003/㎜ | 0.003/㎜ | 0.003/㎜ | 0.003/㎜ | 0.003/㎜ |

Processing

MARUWA can also offer additional processing to meet your requirements.

We have technologies and extensive knowledges about ceramic materials and that's why high reliability of processed substrates can be provided.

-

Glaze

-

Metalization

-

Polishing / Lapping

-

Mechanical Processing